OGM

Photography

Signage

Large format wallpapers

Artwork installation

Illuminated lightboxes

Team shots

Company timeline

Exhibition graphics

ABOUT THE PROJECT

OGM offer a complete plastic injection moulding service that starts with concept and product design, and proceeds through prototyping and tooling to full-scale production of high-quality parts and assemblies. Their client list includes Siemens, Drager, iTero, Perceval and Seldon. Located in Oxfordshire and South Wales, their two manufacturing sites occupy over 92,000 sq ft and contain almost 50 advanced injection moulding machines as well as 3D printing facilities. They also have ISO 7 (Class10,000) cleanroom assembly areas providing an ideal environment for the production of medical and electronics mouldings and components.

All of this was hidden from the view of potential clients, but we wanted to bring the production process to life for visitors – which would allow a visual approach to OGM’s introductory sales pitch, and help them win business through more subliminal means.

Following an initial conversation with the MD, we visited and discussed the development of an exciting project to enhance customer experience to be one of an art gallery installation as they walked along the then-empty corridors of OGM’s offices.

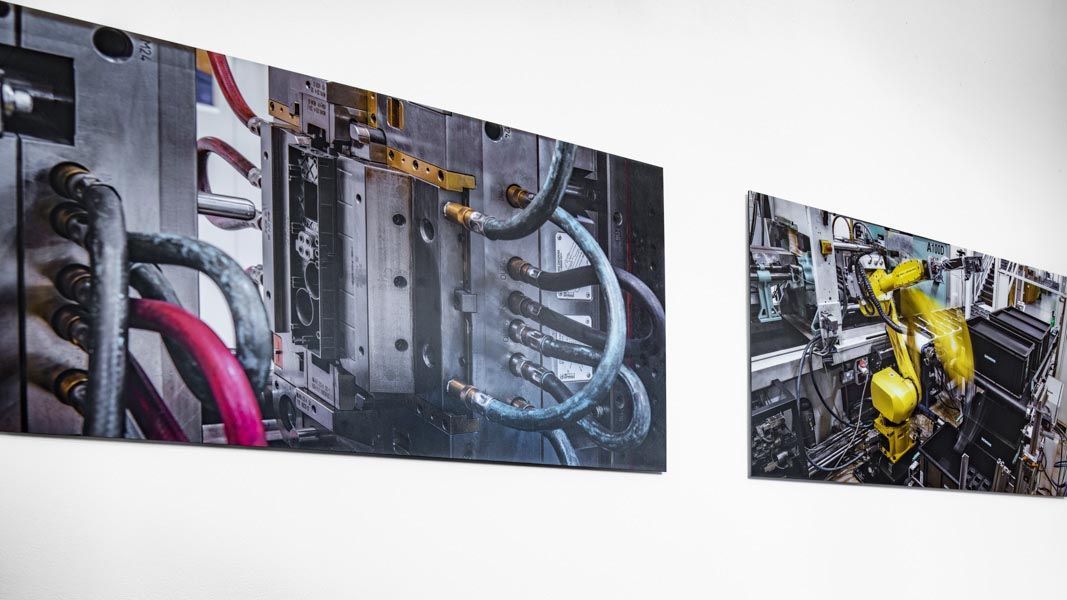

We started by photographing the production process of each product currently being manufactured. This included taking portraits of people – office and design teams, toolmakers, factory-floor staff as well as the material handlers – both human and robotic! We then photographed a wide range of products on-site using our mobile photographic lighting studio.

The real challenge of this project was photographing the working factory environment, which was constantly busy with moving people and robots – and the size of several football pitches! To do this, we used a specialist panoramic gimbal, coupled with wide-format tilt-shift lenses and a 50-megapixel full-frame camera to capture row upon row of perfectly composed images. The next task was to re-assemble all of the final images together, requiring specialist stitching software and many, many hours of meticulous post-production work.

Once all of the numerous photoshoots were finished, we had several thousand high quality images. We selected from these and produced a range of stand-alone images for use in the company social media posts and a number of large-format, wall-mounted illuminated lightboxes showcasing the entire factory, each in one visual sweep.

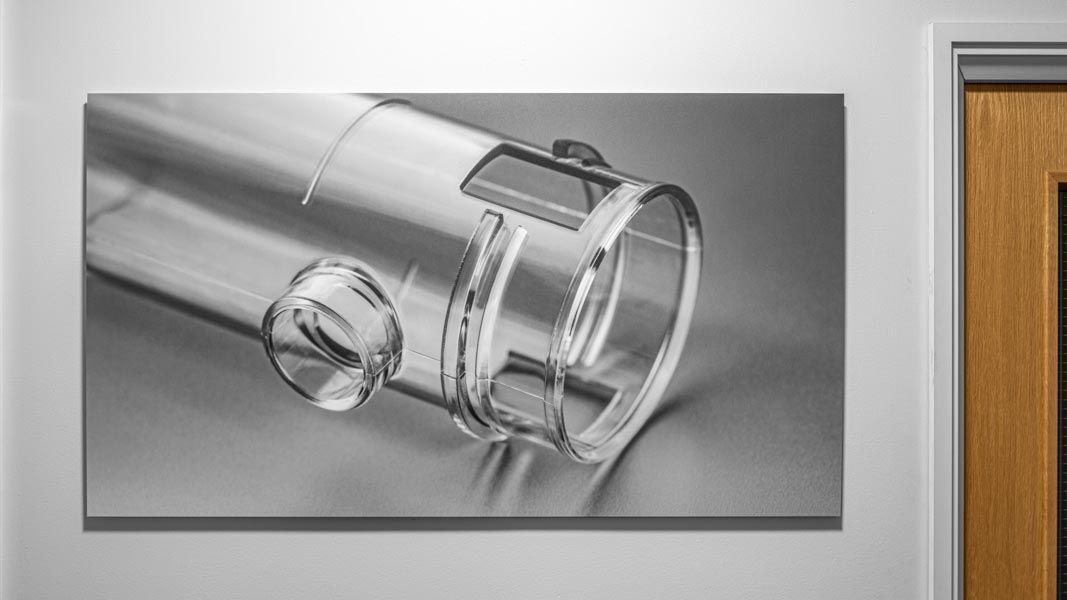

We also produced and installed a range of large-format wallpapers that covered the empty corridor walls with textures of small components – all photographed in our ultra-macro studio that can capture a pinhead quite literally at the size of the side of a bus. Each lightbox and each wallpaper was made up of more than 75 individual high-resolution images which were stitched together at 1,000dpi, pushing the limits of technology to output the finished prints at such a large size.

We also produced and installed a series of freestanding 3D exhibition stands for use in the permanent factory exhibition as well as at trade shows, each documenting one particularly important project for the company whilst at the same time underpinning their ethos of making each product 'Right First Time'.

In addition, we produced a range of large-format vinyl wall-graphics, a custom-printed whiteboard and an impactful series of 30 sequential high-resolution large-format printed images. These were displayed on the route to the company board room in developmental order so that customers could see and understand more of the manufacturing process for a range of key products.

The last of the 30 images were curated in to an art installation, turning an empty corridor outside the MD’s office in to a gallery exhibition of highly polished artful abstracts of plastic components, all with a consistent colour theme to draw the collection together.

Finally, we designed and produced a fabulous reception timeline display showing the company’s history from 1962 to present.

What a project this turned out to be! It’s one we're really proud to call all our own work (with of course a little help from our client, OGM, who were simply brilliant to work with through every step of this multi-faceted project).